The storage dryer concept is a semi-continuous process. The material to be dried is fed into the drying chamber all year round, fully automatically and continuously via an underfloor feeding system.

The advantages of the THERMO-SYSTEM StorageDryer concept

The Electric Mole is used as the turning unit. Drying thus runs completely autonomously. Due to the combined drying and storage function of the concept, a drying hall usually needs to be emptied by wheel loader only 1 time (several times in warmer climates) per year.

Especially for smaller plants and islands, this concept is a simple, low-cost and environmentally friendly solution.

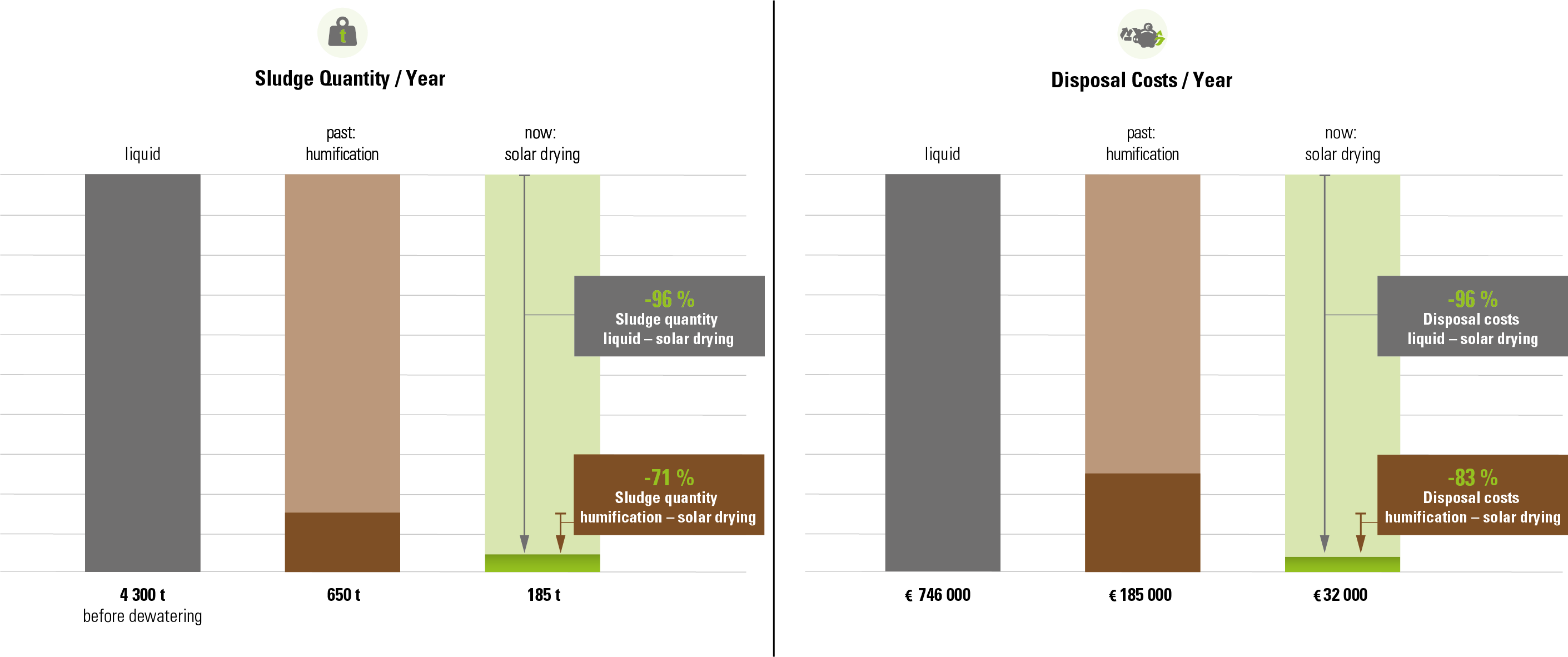

StorageDryer concept | Massive reduction in sludge volume and disposal costs.

Beispiel Langeoog (DE)

Our Plus concepts are the solution of choice when heat energy is available. By introducing additional low-temperature heat, the drying capacity of the plant can be massively increased and the dependence on seasonal fluctuations significantly reduced.

Suitable heat sources include, for example, CHP waste heat, waste heat from industrial processes, biomass heating, heat pumps, etc. For the Plus concept, this additional heat energy can be used from as low as 30-40°C and on a fluctuating basis. Our ClimaControl control system ensures optimum energy utilization. The heat input is provided by air heating coils and/or floor heating.

Our many years of experience (since 1999) and a wide range of applications (realized plants from 50 kW to 20 MW) ensure that extremely economical concepts can be realized even in very confined spaces.

In the storage dryer process, the material to be dried is usually fed into the drying chamber fully automatically and continuously via underfloor feeding. The Electric Mole takes care of fine distribution, turning and mixing. The material is removed by means of a wheel loader; direct loading onto a truck is also possible. We develop and optimize the corresponding tailor-made logistics concepts in close cooperation with our customers.

The optimized process control with the ClimaControl software enables highly efficient drying, as all plant components are controlled and regulated. This approach ensures that drying conditions are constantly optimized and adjusted fully automatically.

All plants are equipped with speed-controlled recirculation and exhaust fans. The recirculation fans on the hall ceiling ensure optimum overflow of the substrate and thus contribute to uniform drying.

The exhaust fans optimize air exchange with the environment and ensure the discharge of saturated air from the drying hall.

Our patented MoviVent system, consisting of speed-controlled recirculation fans on a pivoting unit, contributes to further optimization of drying: the inward and outward pivoting fans remove moisture boundary layer on the sludge surface more effectively and over a wider area, further maximizing drying performance.

Although ClimaControl control minimizes emissions and odors, treatment of exhaust air is useful and necessary under certain conditions, such as unstabilized or poorly stabilized sludge, high local requirements, or close proximity to residential or commercial areas.

Since the optimum exhaust air treatment concept depends on the specific conditions, we use different solutions, such as biofilters or scrubbers, depending on the requirements.